Véto-pharma

Véto-pharma Each year, several thousand of you use treatments to combat Varroa destructor. These treatments are based on different active substances (amitraz, oxalic acid, thymol, formic acid, tau-fluvalinate, etc.) and offer several methods of action and administration routes (rapid action, long action, contact, trickling, sublimation, etc.). But did you know that in Europe, these treatments are registered as veterinary medicines? For instance, the manufacturing of Apivar is strictly supervised by the European and national authorities. Today, we wanted to give you a glimpse of what it is to produce a vet medicine against varroa mites.

A veterinary medicine is a formulation based on an active substance, to which several excipients can be added, that has received a marketing authorization from one or more competent authorities:

Several years are necessary between the start of Research & Development and the Marketing Authorization, during which time the laboratory will complete various steps: search for an active substance, in-vitro tests, preclinical data, clinical data (test in “field” conditions) in order to arrive at the marketing authorization application phase.

To obtain this final authorization, the future Marketing Autorization Holder must prove the quality, efficacy, and safety (non-harmful effect) of the formulation. To that end, then there is the submission of a Market Authorization application, a lengthy and costly procedure containing many studies:

The laboratory must also pay the registration fees to the agency concerned. Once these steps have been completed, the national or European agency validates a “SPC” (Summary of Product Characteristics) which summarizes all the drug’s characteristics (posology, instructions for use, precautions, secondary effects, etc.) and which also defines its framework of use (in particular posology, precautions, and duration of application).

Thus, the laboratory undertakes to comply with the SCP and not promote any use that deviates from this framework (for example, promote an unauthorized duration of treatment, or suggest increasing the dosage).

Then, if we want to sell this vet medicine in the USA, we have to through a registration via the EPA.

If you are not familiar with drug manufacturing, it would be easy to imagine that two drugs containing the same molecule are necessarily identical. This is not true because several elements may vary:

Apivar was developed in France and obtained its marketing authorization in 1995. At the time, it was the second drug to be registered in France for combating Varroa destructor. Its SCP was updated in 2017 in order to add more recent data (efficacy, toxicity, residue).

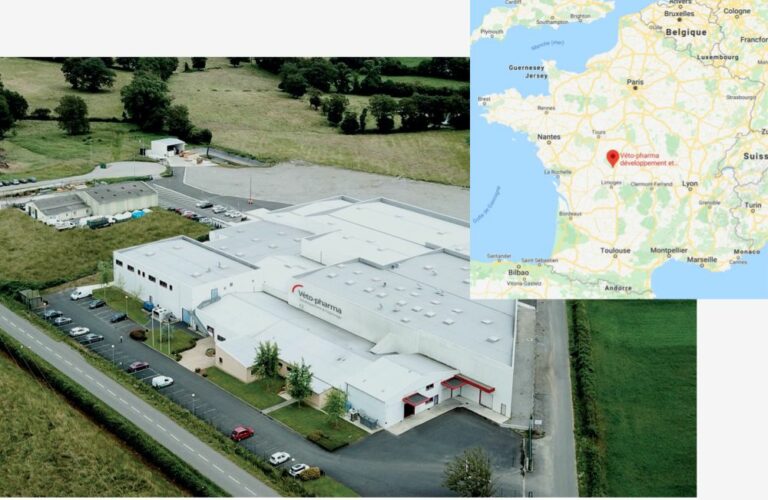

Apivar has been made in France from the very beginning, and more precisely in the center of France, where the Véto-pharma plant is located. We employ about sixty people there (about fifteen in Quality Assurance and Quality Control, and about twenty in production); in addition to the twenty or so employees located in our office near Paris. At the two sites, the team also includes four veterinarians and two pharmacists.

Our plant is GMP (Good Manufacturing Practices) certified, which guarantees compliance with European directives and their quality standards. Indeed it is only possible to manufacture a drug in structures that hold a manufacturing authorisation. GMP are the principles and guidelines to be followed for manufacturing drugs for human and veterinary use. During manufacturing, the same standards are applied to the drug whether it is for human or veterinary use.1

The amitraz used to make Apivar is pharmaceutical quality French amitraz.

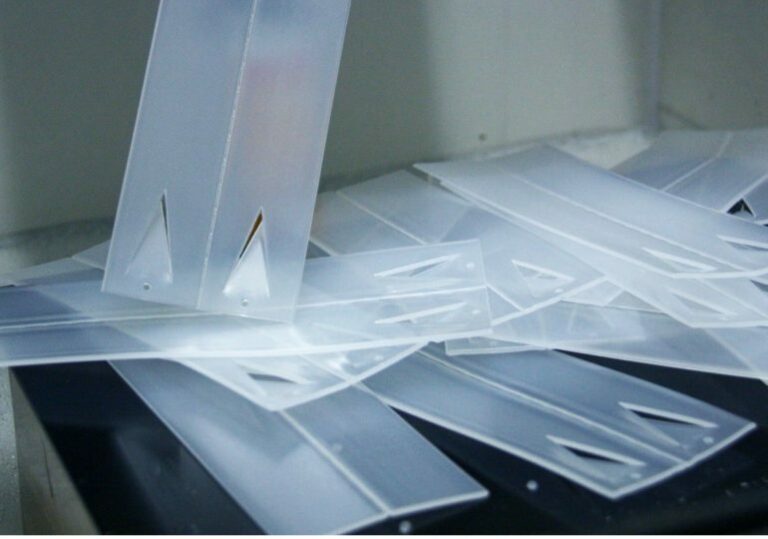

The specific Apivar manufacturing process allows the amitraz to be spread evenly over the entire surface as well as inside the strip.

Each time the bees come into contact with the strip, they “collect” amitraz from the surface. The amitraz located inside the strip migrates to the surface and renews the supply of amitraz available for the bees. This guarantees the controlled distribution of the active substance during all the treatment duration.

Following their production, the strips are then placed in a pack with a specific covering, then vacuum packed to ensure that the amitraz can be stored for up to 2 years after production. Thus, Apivar offers the longest shelf life among amitraz-based veterinarian medicines against varroa mites. In particular, this vacuum pack means that we do not use additional excipients to guarantee the product’s stability.

Each batch of Apivar is subject to many quality tests at each production step:

All these checks are noted in the “batch record” as production progresses.

At the end of production, the Qualified Person reads the entire record and validates whether the batch will be sold or not. If the batch is declared non-conform, it will be removed and destroyed. A sample of each batch is also kept in a “combinatorial library” for 3 years.

After “releasing” the batches, the packs will then be sent all over the world since Véto-pharma distributes Apivar in more than 35 countries. In this way, more than 5 million colonies are treated each year with this French drug and we are somewhat proud of the fact! In 2019, 1,102 batches were sold. This represents many (many!) quality controls.

As a veterinarian pharmaceutical laboratory, our work does not stop with the marketing of the drug. It is also our duty to inform the competent authorities of all cases of pharmacovigilance (namely the presence of potential adverse effects, lack of efficacy, residue or environmental problems) brought to our attention. In addition to the quality checks, this enables monitoring of the safety and efficacy of the drugs released on the market.

The quality, safety and efficacy of veterinarian medicines are controlled by the national regulatory authorities, some of them publishing a surveillance report for veterinarian medicines every year. Analytical controls are performed regularly on veterinary medicines sampled in the field. Batch recalls are organised if quality defects are found.

The marketing life cycle of a Varroa treatment, from R&D to the release of batches, requires the intervention of multidisciplinary teams that contribute to creating a veterinary medicine that complies with regulations. Each person has a role to play in this internal organisation, comparable to the organisation of a colony in which the roles of each one has an impact on the common goal.

Behind a simple pack of Apivar strips, there is collaboration between the Research and Development, Regulatory, Quality Control, Production, Logistics teams, all committed to providing beekeepers with a high-quality treatment.

All of these steps are bypassed in the preparation of unauthorized formula (= not registered as a veterinary medicine) or when using veterinary medicines designed for species other than bees (e.g.: an amitraz-based veterinary medicine for cattle). For this type of preparation, no guarantees can be made concerning efficacy, safety, absence of residue, etc. Do not forget that hive products are for human consumption and, as players in the beekeeping sector, we all have a duty to our end consumers to guarantee the quality of the products they consume.

APV-77-US-N01-12/20